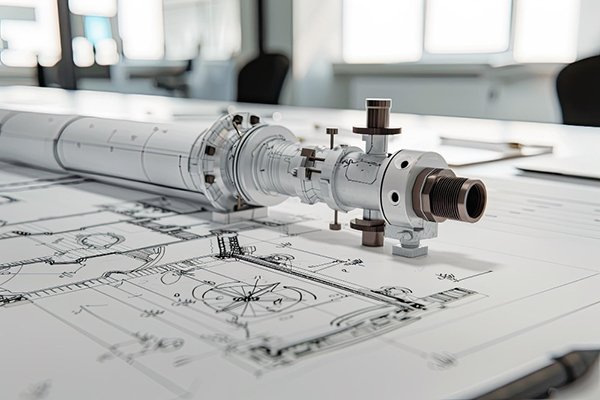

Pipe Drawing Service

Pipe drawing is a specialized cold-working process used to convert round pipes into square and rectangular hollow sections with improved dimensional accuracy and higher mechanical strength. We provide professional pipe drawing services in India for manufacturers and fabrication units that require precise hollow sections with enhanced load-bearing capacity and uniform wall thickness.

This process improves the mechanical properties of the pipe by refining the grain structure and increasing strength without adding material. The drawn square and rectangular hollow sections are widely used in structural, engineering, automotive, and fabrication applications where strength, consistency, and dimensional control are critical.

Process Overview

In pipe drawing, a round pipe is passed through a specially designed die and mandrel to form square or rectangular sections. The cold drawing process reduces tolerances, improves surface finish, and increases mechanical strength due to work hardening. This method produces hollow sections with:

- Accurate corner radii

- Uniform wall thickness

- Improved straightness

- Better dimensional control

The result is a stronger and more consistent product compared to conventionally formed sections.

Materials We Work With

We provide pipe drawing services for a wide range of metals commonly used in Indian industries, including:

Stainless Steel

Alloy Steel

Carbon Steel

Mild Steel (MS)

Precision Steel Tubes

Section Shapes & Size Range

We offer pipe drawing for the following hollow sections:

Square Hollow Sections (SHS)

Rectangular Hollow Sections (RHS)

Size range and wall thickness can be customized based on raw pipe dimensions and drawing feasibility. Close tolerances can be achieved compared to roll-formed sections.

Quality Control & Inspection

Each drawn pipe is checked for:

Dimensional accuracy

Wall thickness uniformity

Straightness

Surface finish

Mechanical property consistency

Test reports and inspection documentation can be provided as per requirement.

Mechanical Advantages of Drawn Hollow Sections

Pipe drawing significantly enhances mechanical performance due to controlled deformation. Benefits include:

- Higher tensile strength

- Improved yield strength

- Better load distribution

- Reduced internal stress variation

- Improved consistency across batches

These properties make drawn hollow sections suitable for demanding structural and engineering applications.

Applications

Structural

frameworks

Automotive and chassis components

Industrial

machinery

Furniture and architectural structures

Material handling

systems

Engineering and fabrication projects

Frequently Asked Questions

Q1. Why choose pipe drawing instead of roll forming?

Pipe drawing provides better dimensional accuracy, tighter tolerances, and higher mechanical strength compared to roll-formed hollow sections.

Q2. Does pipe drawing increase strength?

Cold drawing increases tensile and yield strength due to work hardening of the material.

Q3. Can you draw stainless steel pipes?

We provide pipe drawing services for stainless steel as well as carbon and alloy steels.

Q4. Are wall thickness and corner radius consistent after drawing?

The drawing process ensures uniform wall thickness and controlled corner radii throughout the section.