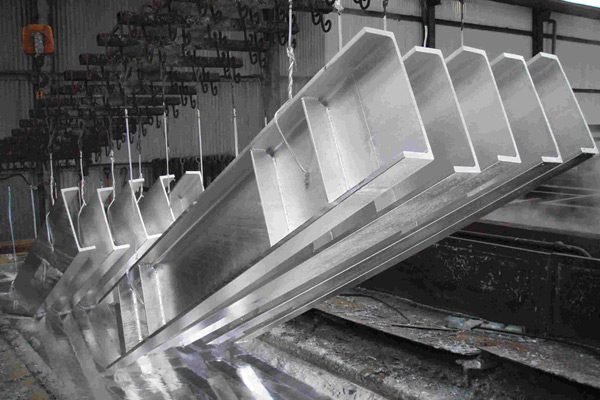

Galvanizing Services in India

Our galvanizing operations are carried out using controlled chemical baths, pre-cleaning systems, and standardized zinc-coating techniques that ensure strong adhesion and consistent coverage. Whether you require galvanizing for structural steel, pipes, cable trays, bolts, frames, or fabricated components, we deliver both batch processing and customized project-based services depending on your requirement.

Why Our Galvanizing Services Are Trusted Nationwide

We follow industry standards such as IS 2629, IS 4759, ASTM A123, ASTM A153, ensuring that every component meets the required coating thickness and performance expectations. Whether it’s heavy structural steel for bridges or lightweight components for fabrication shops, our galvanizing ensures reliable, long-lasting protection.

Materials We Work With

We provide annealing and normalising services for a wide range of metal grades used across Indian industries, including: